If you are interested I have a spare set of the 26Decals, it is the first issue and only has -OQA "Nancy Bird Walton"

This of course is the famous QF32 aircraft that had a small problem on take off from Singapore.

will sell for $15

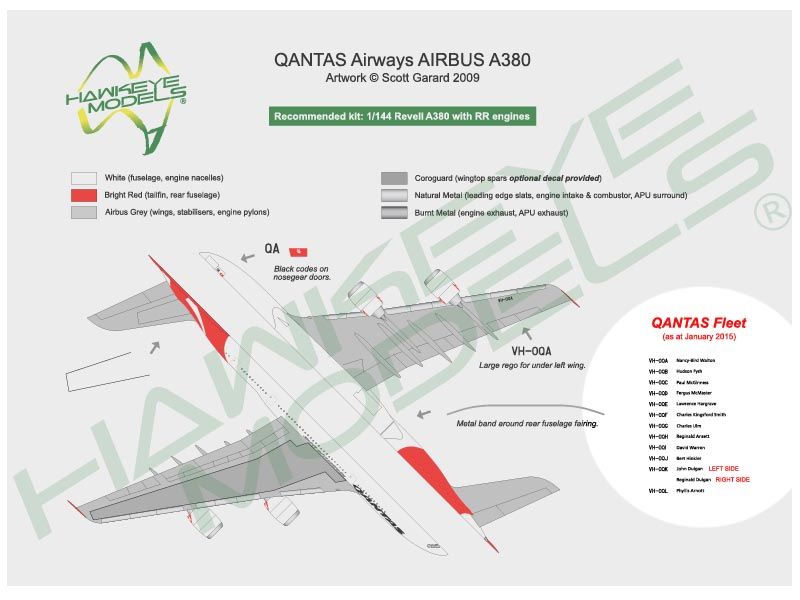

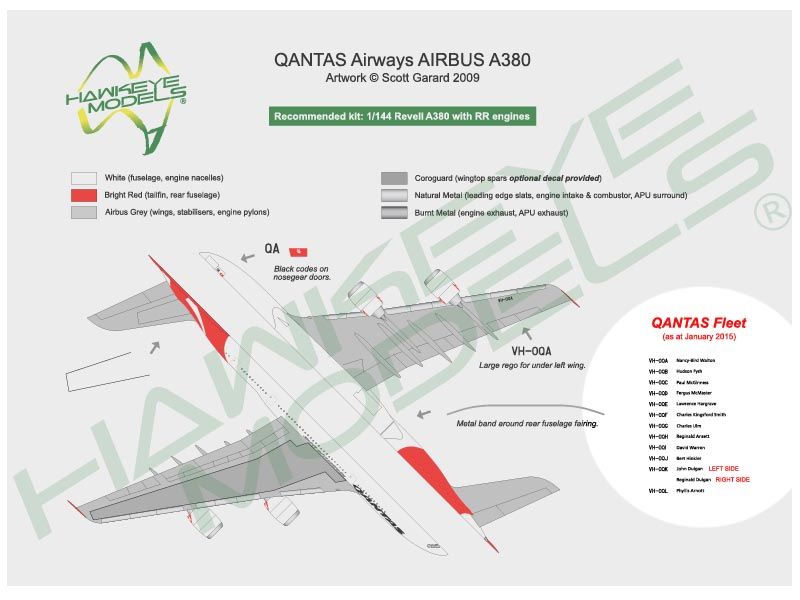

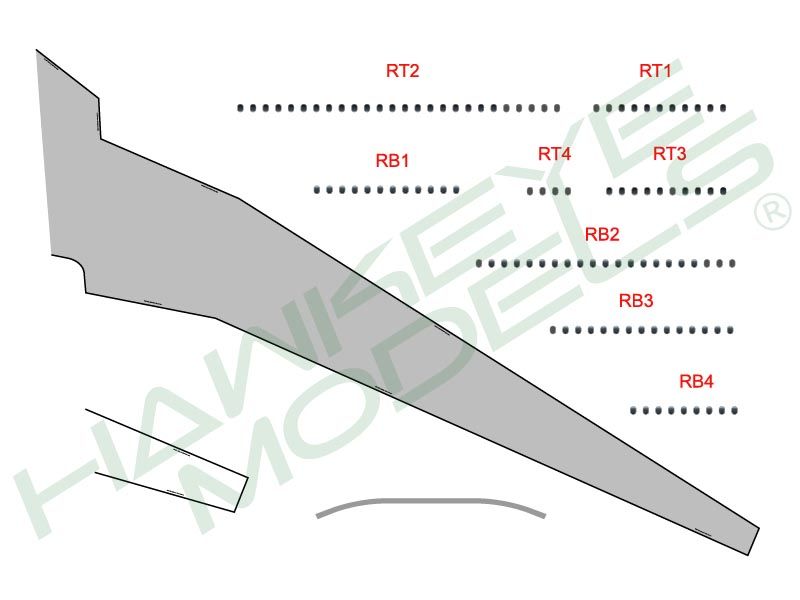

The upside to the new Hawkeye set is that it has the best detail set, in that Scotty captured the inspar area in the correct shape, which is quite complicated, but you will need to fill all the incorrect lines Revell have engraved on the wings.

I guess as it is a commission build, do you really care about total accuracy that much?.

Revell 1:144 A380

42 posts

• Page 4 of 5 • 1, 2, 3, 4, 5

Re: Revell 1:144 A380

Graeme

-

Graeme H - Posts: 1202

- Joined: Thu Jun 05, 2014 12:51 pm

- Location: YBTL TSV

Re: Revell 1:144 A380

hrtpaul wrote:OK that's enough talking about the best aircraft in the world. Back to Troy's QF pregnant hippo

Must have missed it....I don't recall *any* mention of the Piper Aztec..

Pretending to do it TAC style with the big boys since 1987

Also, we don't need no steenkin' VLATs!

Also, we don't need no steenkin' VLATs!

- Cap'n Wannabe

- Posts: 1389

- Joined: Mon Apr 14, 2014 6:00 pm

- Location: Craigieburn, Victoria

Re: Revell 1:144 A380

That's great Ray.....thanks for posting. Just out of curiosity, when was the revised CDS111 released???

TOR

TOR

- tor lives

- Posts: 4295

- Joined: Mon Apr 14, 2014 11:01 am

Re: Revell 1:144 A380

Hi Guys! - I've been catching up on sleep this arvo (shift-worker) and just saw the post.

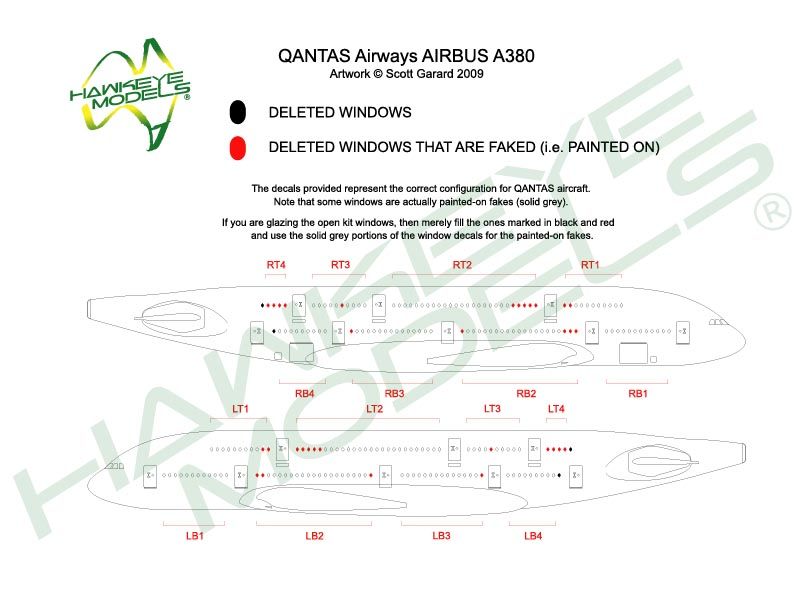

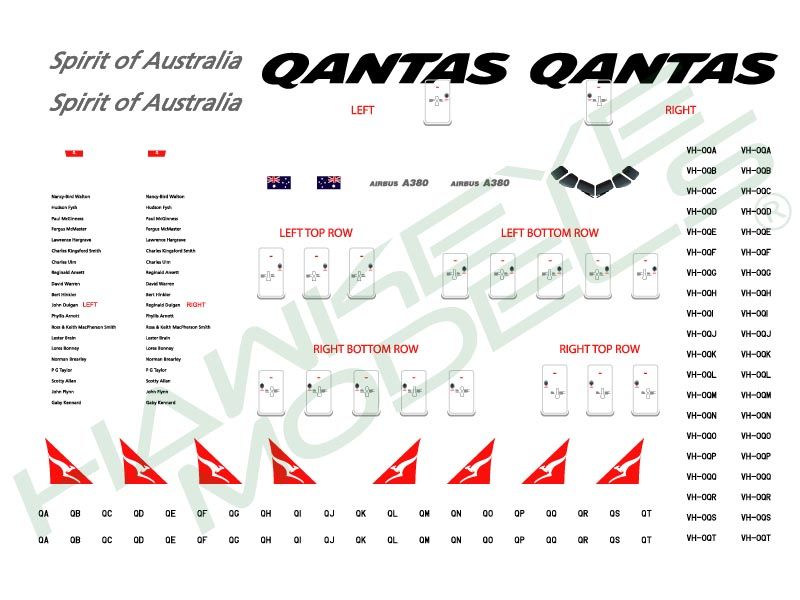

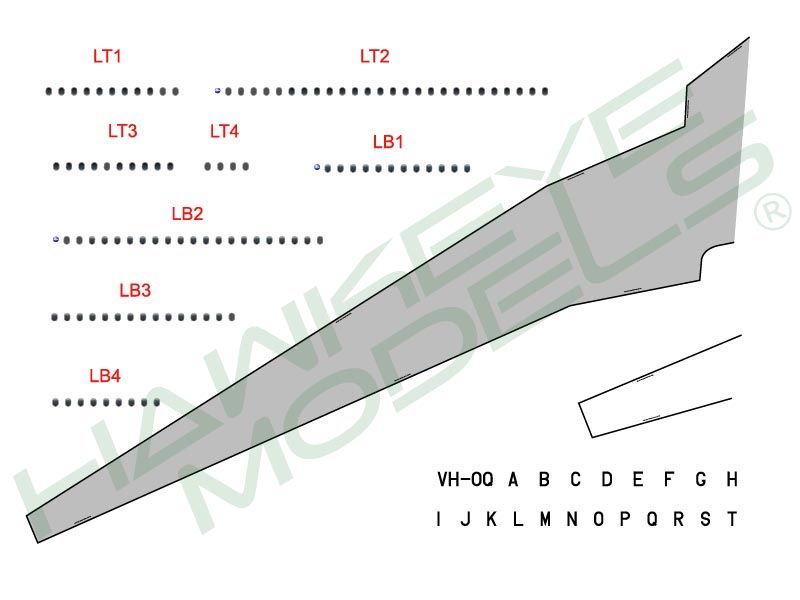

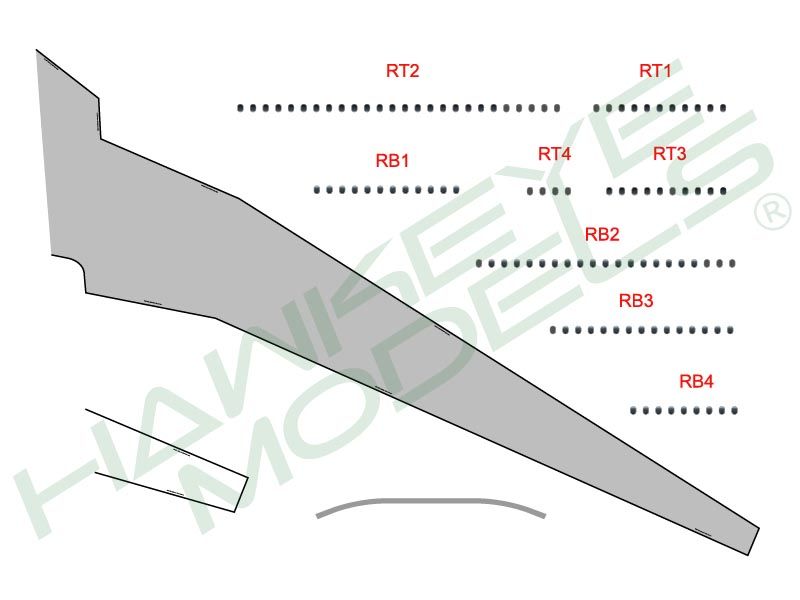

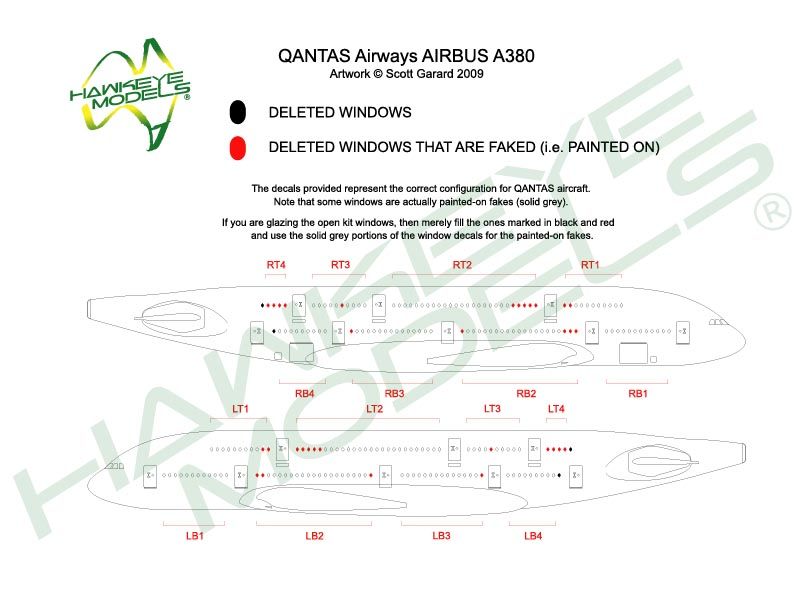

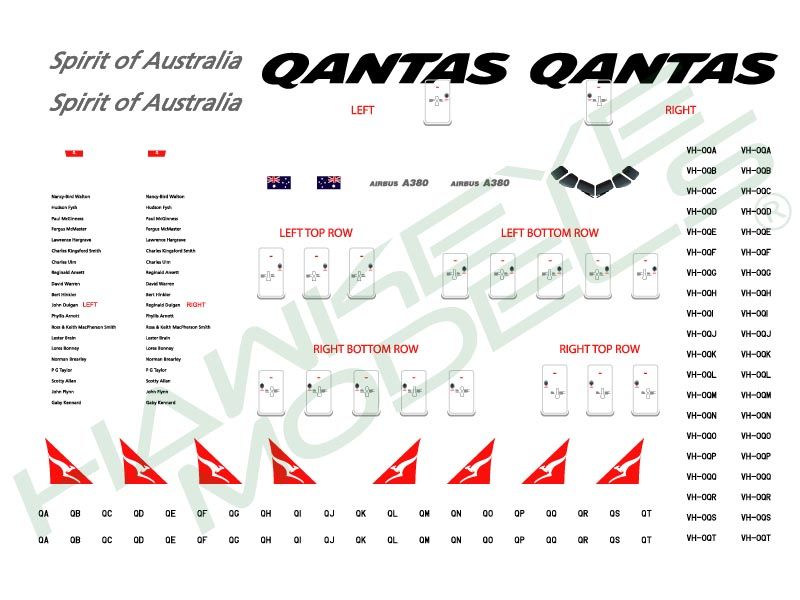

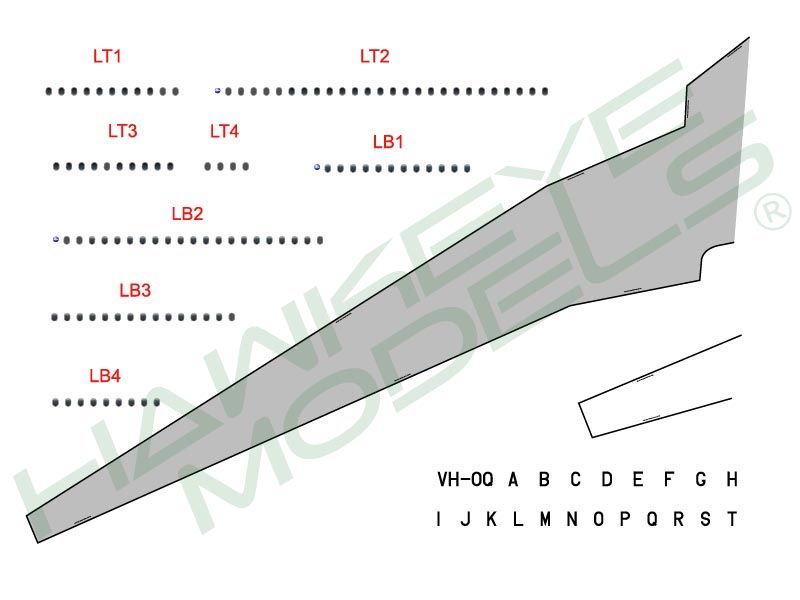

I actually did a slight update and correction for this sheet back in January...

Updated fleet info...

Window config detail unchanged (from first release) ...

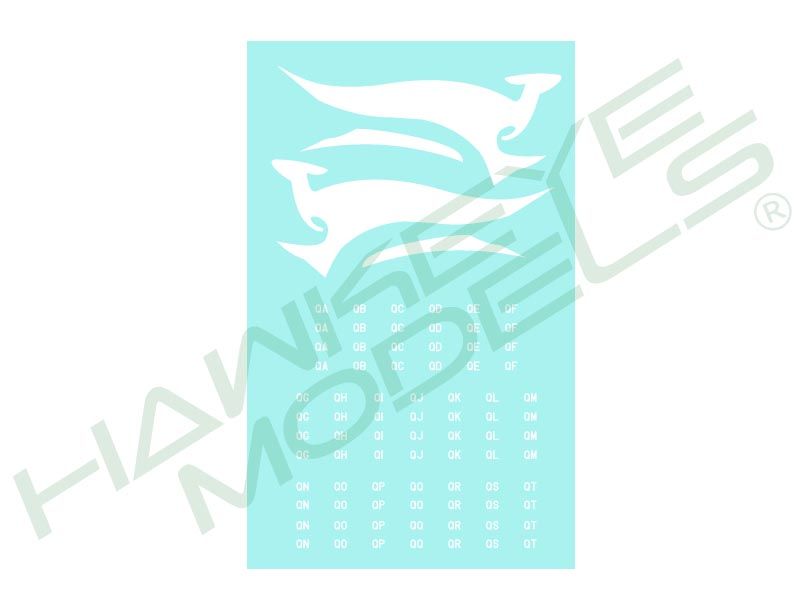

And decal sheets (fixed the shaping of letter D in the regos)...

Scott.

I actually did a slight update and correction for this sheet back in January...

Updated fleet info...

Window config detail unchanged (from first release) ...

And decal sheets (fixed the shaping of letter D in the regos)...

Scott.

Scott Garard

former QF ramper (Thanks alot AJ!)

now Aust Post van driver

former QF ramper (Thanks alot AJ!)

now Aust Post van driver

- scotty100368

- Posts: 397

- Joined: Mon Apr 14, 2014 8:46 pm

- Location: Queanbeyan, NSW

Re: Revell 1:144 A380

Thanks for that Scotty. Is your newest incarnation of the A380 sheet still the same CDS number???.

I will need one of the new sheets because I have a plan to do a diorama of "Nancy" sitting on the ground back in Singapore, all banged up on that fateful day. While I think it is fair to say that I am not an Airbus fan, "Nancy" certainly earned my respect.......she got her crew and passenger home safely under the most extraordinary conditions of damage imaginable, and you can't ask for more than that from any aircraft.

TOR

I will need one of the new sheets because I have a plan to do a diorama of "Nancy" sitting on the ground back in Singapore, all banged up on that fateful day. While I think it is fair to say that I am not an Airbus fan, "Nancy" certainly earned my respect.......she got her crew and passenger home safely under the most extraordinary conditions of damage imaginable, and you can't ask for more than that from any aircraft.

TOR

- tor lives

- Posts: 4295

- Joined: Mon Apr 14, 2014 11:01 am

Re: Revell 1:144 A380

Graeme H wrote:If you are interested I have a spare set of the 26Decals, it is the first issue and only has -OQA "Nancy Bird Walton"

This of course is the famous QF32 aircraft that had a small problem on take off from Singapore.

will sell for $15

The upside to the new Hawkeye set is that it has the best detail set, in that Scotty captured the inspar area in the correct shape, which is quite complicated, but you will need to fill all the incorrect lines Revell have engraved on the wings.

I guess as it is a commission build, do you really care about total accuracy that much?.

Thanks Graeme. I'll be in touch. It's for a 6 year old to hang from the ceiling, so accuracy isn't a primary concern, but I do want to do a good job as far as seams and paint goes.

-

DesTROYer - Posts: 778

- Joined: Tue Jun 24, 2014 9:49 pm

- Location: 37.8136° S, 144.9631° E

Re: Revell 1:144 A380

Those Hawkeye decals sure a a work of art Scotty.

-

DesTROYer - Posts: 778

- Joined: Tue Jun 24, 2014 9:49 pm

- Location: 37.8136° S, 144.9631° E

Re: Revell 1:144 A380

TOR,

I just spoke with Peter and he said that he now uses CDS-111 for this correct version. The old (proposal) scheme is still available on request however.

Scott.

I just spoke with Peter and he said that he now uses CDS-111 for this correct version. The old (proposal) scheme is still available on request however.

Scott.

Scott Garard

former QF ramper (Thanks alot AJ!)

now Aust Post van driver

former QF ramper (Thanks alot AJ!)

now Aust Post van driver

- scotty100368

- Posts: 397

- Joined: Mon Apr 14, 2014 8:46 pm

- Location: Queanbeyan, NSW

Re: Revell 1:144 A380

DesTROYer wrote:Thanks Graeme. I'll be in touch. It's for a 6 year old to hang from the ceiling, so accuracy isn't a primary concern, but I do want to do a good job as far as seams and paint goes.

Not sure if you have done anything with long seams before, but in case not, then superglue is your friend.

My method, others may chip in with different ideas

I usually use MEK (Bunnings plumbing dept) start at the fin then work my way along the top first, as it is the longest and hardest one to do, you get a small amount of working time with MEK, but not much.

I tape up the nose below the windscreen where the glue won't go to hold it together a bit, essential you remove the tape before you go onto that bit.

It is essential you use a small brush to put on the MEK as it is very viscous and will go everywhere, it's the less is more theory.

When that has set up (15 minutes) I then run superglue down the seam on the inside, before doing anymore, let that go off, if you think it is going to go where you don't want it use accelerator.

I will then go around the nose, then along the bottom, this can often take a couple of hours, but if you are careful you will get a seam that will need very little filling, depending on the kit I can often do around aerials without needing filling.

Remember there are a lot of gaps where you can do up to without the glue getting too far ahead of you, the reason I use MEK is that the bond is very quick, less than 2-3 minutes, then superglue on the inside (you can also use epoxy) will ensure the seam won't later split on you.

a lot of people use strips of plastic card across the seam, I feel that the superglue is more than enough, I have dropped kits (yeah I know I'm very clumsy), and never had a seam split.

My personal preference is to use superglue on the outside of the seam as well, especially if you are doing anything with a natural metal finish, as Alclad and such can't tell the difference between superglue and plastic, not that there is much of that on an A380.

Interested in what others do.

Graeme

-

Graeme H - Posts: 1202

- Joined: Thu Jun 05, 2014 12:51 pm

- Location: YBTL TSV

42 posts

• Page 4 of 5 • 1, 2, 3, 4, 5

Who is online

Users browsing this forum: No registered users and 25 guests