As some of you may know, I've had a 3D printer for about a year now. I bought it with the idea that I could make bits and pieces for various models to enhance them, or improve them. However, my initial efforts were disappointing to say the least. Thanks to my son, who's a lot more tech savvy than I am (and I consider myself fairly tech savvy..), the print quality is a whole lot better as we've printed various items such as belt tensioners, a better fan outlet, and other things which served to stabilise the printer head and generally improve the machine's set up.

Up until now, we've been using PLA as our material, but it has disadvantages for modelling. Mainly, it is incredibly tough, which makes it difficult to sand, and most glues don't hold the parts for very long. I've found a 2-part superglue that works OK most of the time...

So recently I ordered some HIPS (high-impact polystyrene), and have printed a couple of test pieces. Firstly, it sands very well. It is slightly harder than "normal" polystyrene, and slightly more flexible, but it is incredibly easy to sand. And possibly the best part is that modelling cement such as Tamiya extra thin, or Revell Contacta work in exactly the same way as with a model, ie, the plastic parts are "welded" together.

Over the next few weeks, I'll be experimenting to find out just how fine I can print, and then having a look at modelling a complete aircraft...

Watch this space..

3D printing

25 posts

• Page 1 of 3 • 1, 2, 3

3D printing

Pretending to do it TAC style with the big boys since 1987

Also, we don't need no steenkin' VLATs!

Also, we don't need no steenkin' VLATs!

- Cap'n Wannabe

- Posts: 1390

- Joined: Mon Apr 14, 2014 6:00 pm

- Location: Craigieburn, Victoria

Re: 3D printing

Mate that's awesome. I'd love to get into 3d printing for models but considering I don't know about CAD and my Silhouette Portrait Cutter is still sitting in it's box for the last 2 years, I probably shouldn't get a 3D printer anytime soon

Head A/CAM Phantom Phanatic, Shit Stirrer and Karma Bus Driver toot fkn toot

- hrtpaul

- Posts: 4165

- Joined: Sat Apr 12, 2014 10:44 am

- Location: Like I'm gonna tell you lot

Re: 3D printing

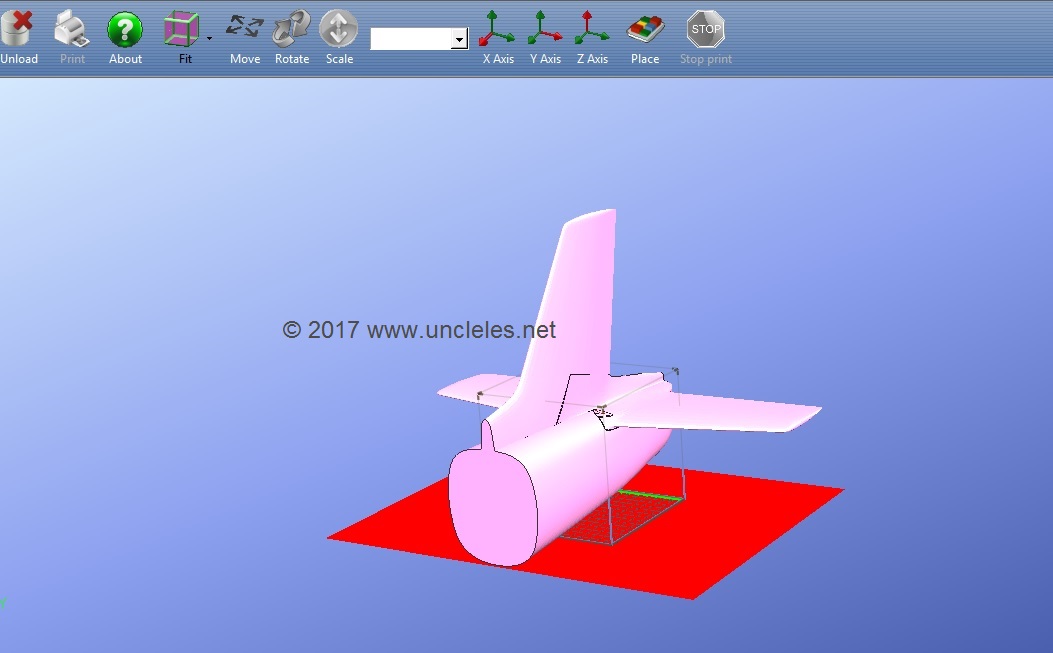

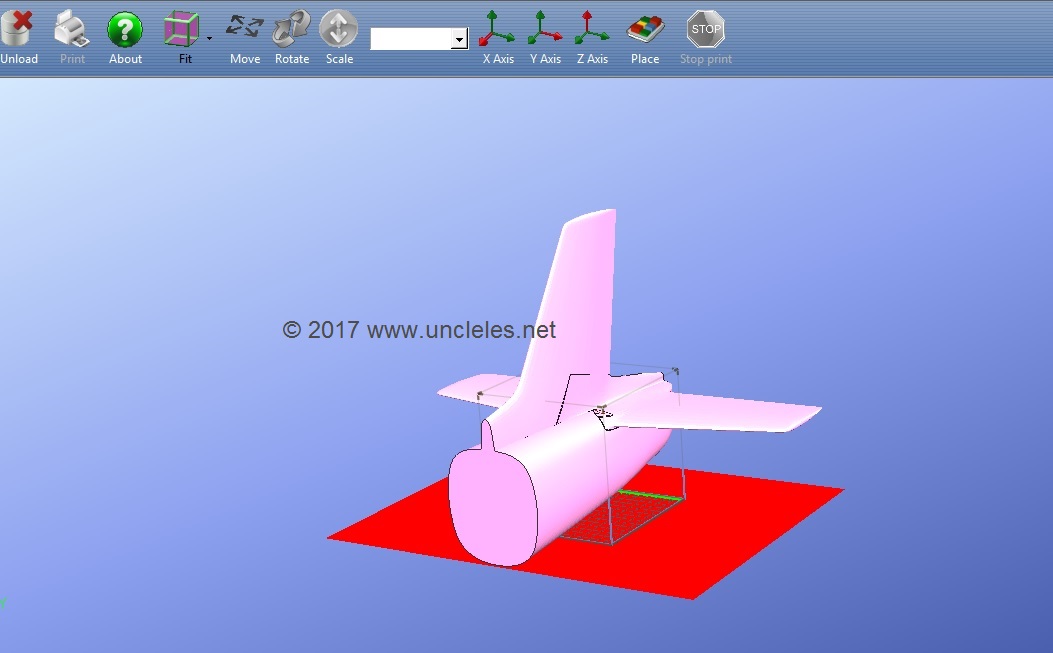

So today I've been mucking around with the fuselage side of my Islander. It still needs some tweaking around the nose/canopy area, but it's a start. Gonna be a while before it's finished, too! A long, long while...

The next thing to do is to the fuselage profiles. I may have to sacrifice one of my 8 BN-2 kits (if only I'd kept the one my ex-girlfriend started

)

)

The next thing to do is to the fuselage profiles. I may have to sacrifice one of my 8 BN-2 kits (if only I'd kept the one my ex-girlfriend started

Pretending to do it TAC style with the big boys since 1987

Also, we don't need no steenkin' VLATs!

Also, we don't need no steenkin' VLATs!

- Cap'n Wannabe

- Posts: 1390

- Joined: Mon Apr 14, 2014 6:00 pm

- Location: Craigieburn, Victoria

Re: 3D printing

keep pluggin' away ! I'm here to tell you it's well worth it in the end !

My first effort was the wing for my 1/32 DHA Glider :

http://uncleles.net/2016/04/05/dha-glid ... wo-scales/

Then I progressed into whole airframes:

http://uncleles.net/2017/06/06/132-macc ... he-making/

It's all good !

My first effort was the wing for my 1/32 DHA Glider :

http://uncleles.net/2016/04/05/dha-glid ... wo-scales/

Then I progressed into whole airframes:

http://uncleles.net/2017/06/06/132-macc ... he-making/

It's all good !

- uncle les

- Posts: 100

- Joined: Mon Oct 06, 2014 12:12 pm

Re: 3D printing

Stop showing off. Both of you

Head A/CAM Phantom Phanatic, Shit Stirrer and Karma Bus Driver toot fkn toot

- hrtpaul

- Posts: 4165

- Joined: Sat Apr 12, 2014 10:44 am

- Location: Like I'm gonna tell you lot

Re: 3D printing

uncle les wrote:Then I progressed into whole airframes:

http://uncleles.net/2017/06/06/132-macc ... he-making/

What program are you using there, Les?

Pretending to do it TAC style with the big boys since 1987

Also, we don't need no steenkin' VLATs!

Also, we don't need no steenkin' VLATs!

- Cap'n Wannabe

- Posts: 1390

- Joined: Mon Apr 14, 2014 6:00 pm

- Location: Craigieburn, Victoria

Re: 3D printing

Mate I hope you weren't thinking of doing a 1/48 Islander

http://www.airlinercafe.com/forums.php?m=posts&p=70024#70024

http://www.airlinercafe.com/forums.php?m=posts&p=70024#70024

Head A/CAM Phantom Phanatic, Shit Stirrer and Karma Bus Driver toot fkn toot

- hrtpaul

- Posts: 4165

- Joined: Sat Apr 12, 2014 10:44 am

- Location: Like I'm gonna tell you lot

Re: 3D printing

hrtpaul wrote:Mate I hope you weren't thinking of doing a 1/48 Islander

http://www.airlinercafe.com/forums.php?m=posts&p=70024#70024

No problem....I'll just make mine 1/32 then. Easy as

Pretending to do it TAC style with the big boys since 1987

Also, we don't need no steenkin' VLATs!

Also, we don't need no steenkin' VLATs!

- Cap'n Wannabe

- Posts: 1390

- Joined: Mon Apr 14, 2014 6:00 pm

- Location: Craigieburn, Victoria

Re: 3D printing

Cap'n Wannabe wrote:What program are you using there, Les?

Rhino, UP3D, Meshlab, 3DBuilder, Paint3D, Sketchup & Photo2Mesh. All have pros & cons.

hth.

- uncle les

- Posts: 100

- Joined: Mon Oct 06, 2014 12:12 pm

25 posts

• Page 1 of 3 • 1, 2, 3

Who is online

Users browsing this forum: No registered users and 36 guests