Work on this slowed for the last couple of days as I got things shipshape for my wife's return from the UK. My spare bench inside the house has been dismantled and put away..(pity it was damn useful!) then.. having a missus is better than having a spare bench so I can't complain:smile:.

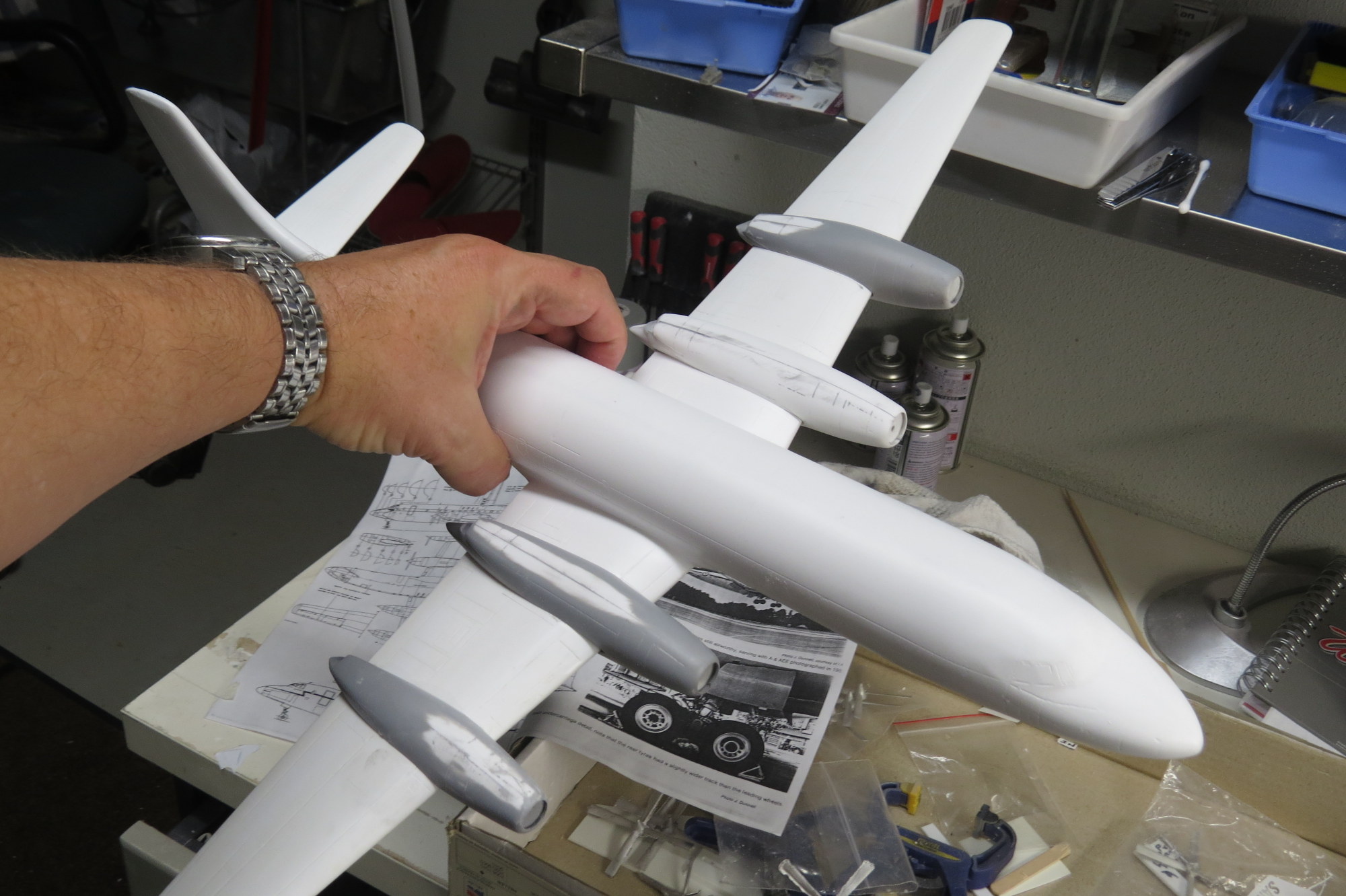

She's back and I got a few hours in on the Britannia, my mission was to do the exhaust / jet pipes. I found aluminium tubing at the local hobby shop in various sizes, I used the K&S tube cutter to cut off the short lengths required. Drilled holes of increasing diameter in the apoxie sculpt - filled rear nacelles filed to shape and put in the slightly flattened tubes. Each engine took at least 30 mins work, they are not perfect but many hundreds of percent better than what they were I still have to "dress up" the exhaust areas put an endplate in so you cant see through all that will be done as the same time as all over seam filling and sanding... lots and lots of it..sigh